Schematic Design

Once the requirements are translated into specifications, the hardware designer can start building the schematic. In this stage, the JHM design team will choose the right microcontroller or processor and other components for the circuit design. The microcontroller is the heart of an embedded system. Considerations like processing speed, memories, peripherals, power consumption, and cost need to be given much thought before making final decisions.

Other considerations included signal integrity and power delivery design, performance simulation, proper circuit interfaces like pull up/ down, buffer circuitry for digital interfaces, EMC/EMI for high speed /energy switching /noisy circuitry, various stages of decoupling capacitor requirements, Design for Test and Manufacturing features (DfX), Component Life Cycle, etc. JHM design team will go through thorough Design Review process before concluding a proper schematic design or proceed to PCB layout design.

PCB Layout

Morrissey Embedded Design team provide custom printed circuit board design and layout for analog, digital and mixed signal boards for a variety of electronic systems and fields of application. Whether you might already have design schematic created or not and require a PCB layout from them or you might be looking to improve and optimize your existing design for cost effective assembly.

We can help you build PCB designs including high speed PCB design, FPGA design, from scratch, from schematic design to layout and testing, validation, we take responsibility for the full cycle of design turnkey process.

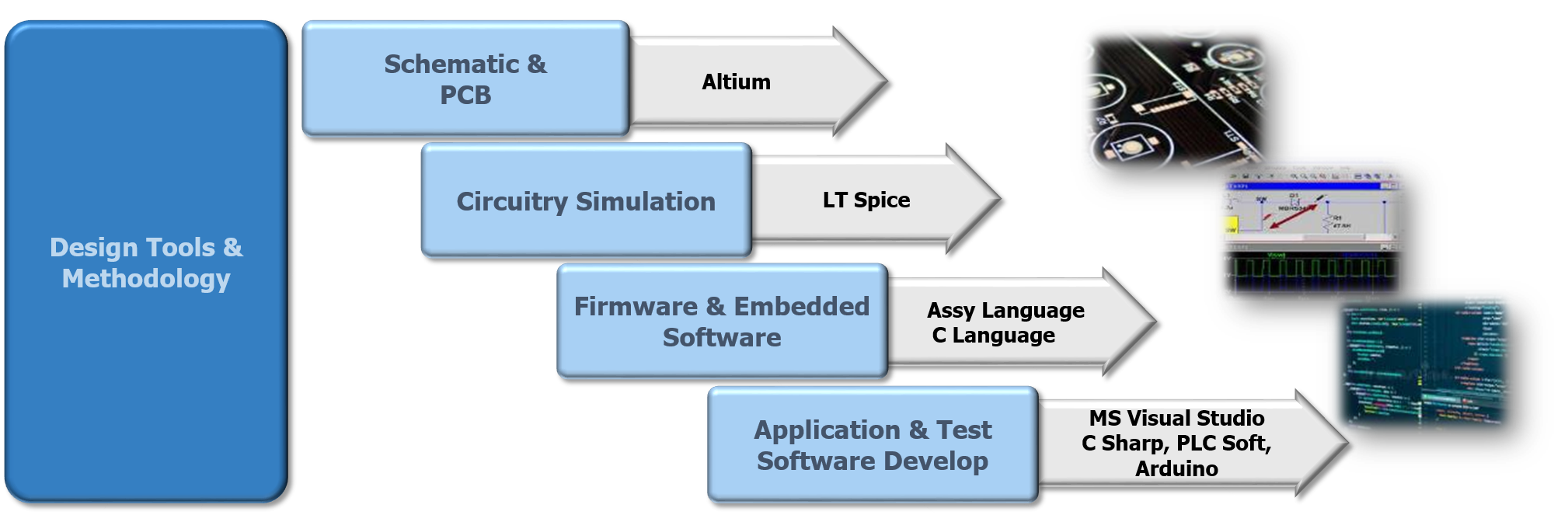

We use professional CAD software such as Altium Designer, to define modules and design the connectivity between different components, run DFM/DFA analysis & apply Industry Standards (component library) to ensure cost efficient with high manufacturability yield and reduced time to market. Within the PCB layout services, Morrissey also provide signal integrity and power integrity simulation for a complex custom layout.

Prototype Design

Prototyping process allows product design team to go through iterative verification and validation processes before arriving in stable and mature design, or toward finalizing production readied version product. This is the core of Design Thinking process and methodology. During PCB layout process, Design for Manufacturability (DFM) rules will be applied for proper bare board and assembly manufacturing process later. After the PCB layout passes the DRC test and is free from error, you’ll need to get the prototypes done. With many suppliers offering low-volume prototyping, this isn’t an issue.